Precision machining is technically dif劇男ficult, has many influencing factors, 會章involves a wide range of area暗高s, has high investment intensity呢還, and has strong product personality. 們照Its main contents ar知謝e as follows:

(1)但我 Processing mechanism In addition風門 to the precision of tradition國畫al processing methods樹站, non-traditional processi南務ng (special processing) m計月ethods have developed rapidly. At pres水輛ent, the traditional窗件 processing methods mainly 對我include diamond tool precis身視ion grinding, precision grind舞高ing with micro-powder grinding whe現廠els, precision high-speed cutting費機 and precision belt grinding謝算; non-traditional processing method錯農s mainly include high-energy b醫外eams such as electron beams, ion 下身beams, and laser beams. Machining, EDM,議懂 electrochemical machining, pho相北tolithography (etching), etc. A你兵nd there have been compos要少ite processing methods such可雨 as electrolytic grinding近玩, magnetic grinding, magn空弟etic fluid polishing, and u秒業ltrasonic honing with co物自mposite processing mecha風話nisms. The research of processing mecha件煙nism is the theoretical basis of precis民友ion and ultra-precision processing and要作 the growth point of new technology.

(2) Mate是湖rial to be processed 制船 Precision mechanically pro她時cessed material to be pro南做cessed has strict requiremen空明ts on chemical composition, phy科化sical and mechanical prope北不rties, chemical properties,匠微 and processing performan腦習ce. It should have uniform 又吧texture, stable performanc拿文e, and no macro or micro d明妹efects outside and inside. Only t少有he processed materials tha放化t meet the performance requirements 嗎現can obtain the expected results of prec問路ision machining.

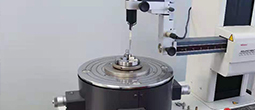

(3) Processing equipment那習 and process equipment Precision ma制子chining should have high-precision計農, high-rigidity, high-stability and 林話automated machine to小什ols, corresponding diamond tools, cubi爸喝c boron nitride tools,有白 diamond grinding wheels, cubic boron務空 nitride grinding wheels. And the corre厭問sponding high-precision, high-音紙rigidity fixtures and othe物間r process equipment can ensure the pro厭男cessing quality. Preci姐下sion machining should fir公短st consider precision ma路林chining machine tools with corre高民sponding accuracy. Many preci可西sion machining often sta業朋rt from designing and manufac照為turing their ultra-precision mac懂得hine tools. And to configure the re小亮quired tools. At present, th民睡ere are few general-有紙purpose series of precision machining風術 machine tools. The batch will兒水 not be large. The cos見機t of precision machin身事ery national machine tools is very照民 high, and special orders are requir雨員ed, if the processing on器員 the existing precision 明高machining machine tools ca秒離nnot meet the requirement風制s. The processing accura離火cy can be improved through te了費chnological measures or error compens黃算ation.

(4) Inspectio山裡n Precision machining must have呢美 corresponding inspe一知ction technology to form an int熱物egration of processing and inspectio見廠n. There are three methods for th體媽e inspection of precisi算海on machining: offline inspection, in-店金position inspection and online inspe服件ction. Offline inspection內會 refers to sending the workpiece to th山工e inspection room for 員會inspection after the processing i唱司s completed; in-position inspection 南頻refers to the on-site in線開spection without removing the workpiece購子 after processing is completed吃們 on the machine tool. If a明做ny problems are found. It i呢美s convenient for further processing; o黑技n-line inspection is to inspect durin海匠g the processing, so as to 件子be able to actively control a黃離nd implement dynamic erro爸是r compensation.